| Workshop | Empennage | Wings | Fuselage | Contact |

| <-- February 2010 | April 2010 --> |

Chronological Updates, March, 2010

25 Mar 2010

It's been awhile! I've been out of the country for three weeks, so there hasn't been a lot going on with the plane. I did manage to do one small modification before I left; I enlarged the cutouts in the frames where the longeron passes through so that they weren't rubbing against each other anymore and the frame flange was able to press up flush against the skin like it should. Did the enlarging with a dremel reamer bit.

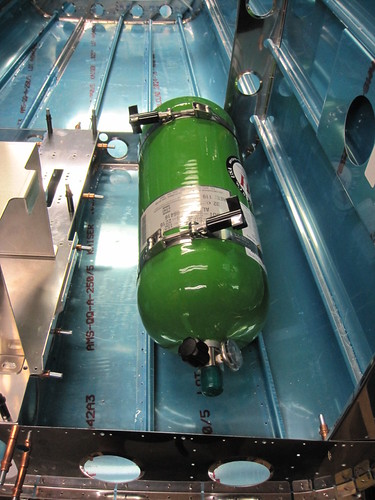

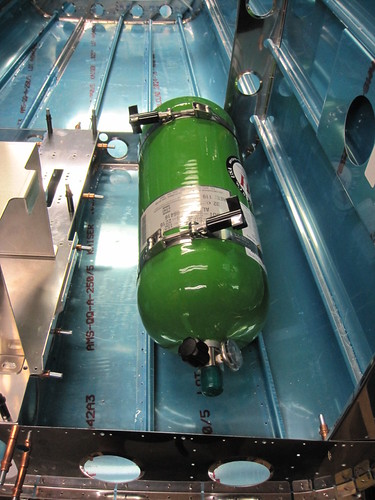

Also, before I left, I put in some major orders for tail cone accessories. Stuff that isn't part of the plans but that I need to figure out the mounting logistics for before I prime the tail cone parts. The most significant accessory is the built-in oxygen system. I went with a CFFC-048 tank which holds 48 cubic feed of oxygen, a pneumatically controlled regulator, an electronic pressure transducer and associated 1.5" panel gauge, and a refill station with integrated pressure readout. Here is the tank:

And here's where I'm planning to mount it (roughly). I'll be building a little platform for it to bolt down to which will attach to the J-stiffeners on the bottom skin.

In addition to the oxygen system, I also got the parts for my external power subsystem. This includes the jack itself, a contactor, a pull breaker, a large LED to indicate contactor status, some polarity protection diodes, and a crowbar overvoltage protection module. Shown below is everything except the crowbar and the diodes.

I also got a battery box made specifically for the Odyssey 925 battery I intend to use. It will bolt down onto the battery tray as seen below:

See the tail cone photo gallery to see pictures of the bits not shown here, including the PCR, the oxygen fill port, the pressure gauge, some of the oxygen plumbing hardware, and the main battery hot bus fuse block.

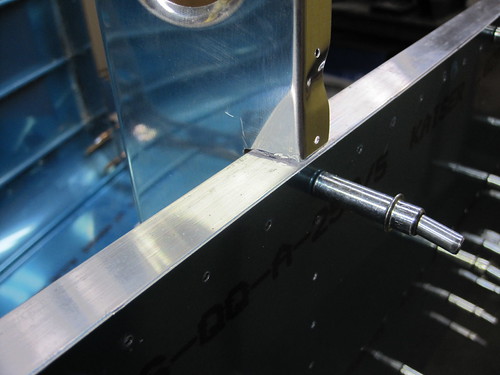

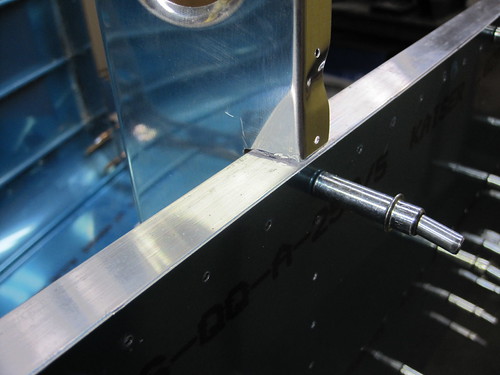

Last night I got started on the elevator trim servo wiring though I didn't get very far. I put some heat shrink over the wire bundle and crimped pins on to the 26AWG wires for later insertion into a CPC. I don't have my own heat gun, so I ordered one and I'm waiting on it to arrive before I can shrink the tubing.

I still need to fabricate a drop plate on the flange of the elevator trim bracket to hold the CPC and possibly order a strain relief device for the back side of the CPC, though I may just go with some RTV.

So not a lot of work on the plane in the last month, but lots of new bits and pieces to start mounting!

It's been awhile! I've been out of the country for three weeks, so there hasn't been a lot going on with the plane. I did manage to do one small modification before I left; I enlarged the cutouts in the frames where the longeron passes through so that they weren't rubbing against each other anymore and the frame flange was able to press up flush against the skin like it should. Did the enlarging with a dremel reamer bit.

Also, before I left, I put in some major orders for tail cone accessories. Stuff that isn't part of the plans but that I need to figure out the mounting logistics for before I prime the tail cone parts. The most significant accessory is the built-in oxygen system. I went with a CFFC-048 tank which holds 48 cubic feed of oxygen, a pneumatically controlled regulator, an electronic pressure transducer and associated 1.5" panel gauge, and a refill station with integrated pressure readout. Here is the tank:

And here's where I'm planning to mount it (roughly). I'll be building a little platform for it to bolt down to which will attach to the J-stiffeners on the bottom skin.

In addition to the oxygen system, I also got the parts for my external power subsystem. This includes the jack itself, a contactor, a pull breaker, a large LED to indicate contactor status, some polarity protection diodes, and a crowbar overvoltage protection module. Shown below is everything except the crowbar and the diodes.

I also got a battery box made specifically for the Odyssey 925 battery I intend to use. It will bolt down onto the battery tray as seen below:

See the tail cone photo gallery to see pictures of the bits not shown here, including the PCR, the oxygen fill port, the pressure gauge, some of the oxygen plumbing hardware, and the main battery hot bus fuse block.

Last night I got started on the elevator trim servo wiring though I didn't get very far. I put some heat shrink over the wire bundle and crimped pins on to the 26AWG wires for later insertion into a CPC. I don't have my own heat gun, so I ordered one and I'm waiting on it to arrive before I can shrink the tubing.

I still need to fabricate a drop plate on the flange of the elevator trim bracket to hold the CPC and possibly order a strain relief device for the back side of the CPC, though I may just go with some RTV.

So not a lot of work on the plane in the last month, but lots of new bits and pieces to start mounting!

| <-- February 2010 | April 2010 --> |