| Workshop | Empennage | Wings | Fuselage | Contact |

Rudder Construction

Current status: Complete, except fairing and rudder trim modification.

Time invested on this sub-assembly: 50 hours (46 by me)

I'm planning on adding a rudder trim modification to the rudder as well as an LED NAV/strobe light at the back of the lower fairing. There will therefore be some wiring runs within the rudder and some means of routing wire from the rudder, through the bottom of the vertical stabilizer rear bulkhead, and into the aft end of the tailcone.

For the trim modification, I'll be using a Ray Allen T2-7A servo to drive a cut-out section of trailing edge. I like the aesthetics of this style of rudder trim more than the Tim Olson style hinge-on-trailing-edge, though it does require considerably more work.

The vertical stabilizer parts are all fabricated and awaiting primer, but I need to get some long lumber to make my part prep tanks and I don't have access to my truck this week. So I shelved the VS parts and started on the rudder. No marathon sessions this week, just an hour here and there. Total of about four hours over various lunch breaks and after dinner cleco sessions.

The first step was to lay out all of the rudder parts for a group shot. The only thing missing here is the electrical connectors, wire, and skins.

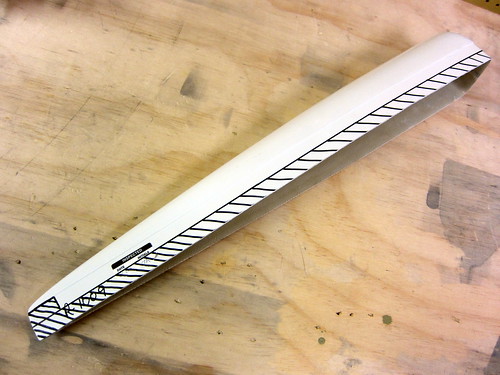

Just like with the vertical stabilizer, the rudder starts out with some bandsaw cuts. In this case, a bunch of smaller pieces are joined together with little tabs for ease of manufacturing. It was a reasonably quick piece of work to turn seven identical pieces of angle aluminum and three other punched sheets into these 25 parts:

The pieces for the rudder went together astonishingly quickly; it didn't take long at all to get to the point where I was putting skins on for the first time.

The last thing I did before leaving town for the weekend was put the second skin on in preparation for final drilling.

At this point, I'll probably just finish up with the final drilling and dimpling of all rudder pieces and do all of the priming of both VS and rudder together in one shot to minimize painting overhead.

19 Oct 2009

Over the last two days, I've put in four more hours preparing parts for the rudder. Despite the relatively small number of hours, some significant work was accomplished.

I match drilled all of the holes in the rudder skin, then disassembled the rudder completely and deburred all of the skeleton parts and dimpled the ribs, stiffeners, and spar. I also made some changes for the planned electrical wiring within the rudder.

The plan is to have a wire bundle hanging out the back end of the tailcone beneath the bottom of the lower rudder rib but above the bottom of the lower rudder fairing. A hole will be made in the lower fairing that will allow this cable to enter the fairing during normal operation. The wire will connect to a circular plastic connector attached to the bottom of the lower rudder rib, and from there the cables will split into two groups. The first group will just connect to the tail light at the aft end of the fairing. The second group will pass through a snap bushing in the lower rib and then travel up through three of the stiffeners to the area where the rudder trim modification will eventually be made.

For the time being, the wire bundle will just end in another CPC between the C and D stiffeners. I'll make the cuts for the rudder trim after the rudder has been riveted together. In order to safely pass the wires through the triangular holes in the stiffeners, I drilled out one of the unused holes in each of the left side stiffeners to which I plan to rivet some of the lightening hole wire tie attach brackets. These should keep the wires out of contact with the metal. Thus, the modifications to the three stiffeners were composed simply of final drilling three holes.

The lower rib was a bit more complex. First I fabricated a small angle flange to attach the CPC to.

This, in turn, will get riveted to the bottom side of the lower rib.

Finally, a 3/8" hole was drilled aft of the CPC flange in the lower rib for the snap bushing through which the trim servo wires will pass. That's it for parts fabrication for the rudder wiring. I disassembled the lower rib and modified flanges, deburred everything, and dimpled them where appropriate.

All that remains before priming of the rudder is to make the bend at the trailing edges of the skins, deburr the skins, and dimple the skins.

20 Oct 2009

Nothing momentus happened today; spent about an hour deburring both sides of both rudder skins. Need to figure out the right way to make the bend in the trailing edge before I proceed to dimpling.

29 Oct 2009

A bunch of random things have occurred in the last week. After reading up on other builders websites, I determined that I wouldn't be making the bend in the trailing edge of the rudder at all. I'll be using the angle iron backrivet technique and tank sealant to ensure a good bond at the trailing edge.

Making this decision cleared me to finish up the rudder skins. I removed the vinyl coating from the rivet lines and Bob assisted with the dimpling of all the holes. The next step on the skins will be to scuff the inner surface, clean it, and then prime it.

I spent a lot of time thinking about how to do bond straps between the rudder and vertical stab. I was unable to find appropriate ring terminals, bolts, washers, and nuts in aluminum... so I've decided to use passivated cadmium-plated steel hardware instead and hope for the best. I ordered some candidate pieces from Aircraft Spruce and they look like they might work. I also ordered hardware for making the vertical stabilizer and lower rudder fairings removable via nutplates. Unfortunately I based my parts decisions here on another builder's website who had a typo in their part numbers! I ordered thirty K1000-6 nutplates instead of K1000-06 nutplates without checking the bolt size vs. nutplate size. That's a $50 oops! Reordered the correct nutplates from Van's. They'll be here long before I'm ready for them. If anyone needs any of the huge K1000-6 nutplates... let me know.

The other major accomplishment of this week was building the dunk tank for doing alumiprep and alodine chemistry on the long thin parts of the aircraft. I didn't want to have to build more than one of these, so I made it really long to accomodate the longest pieces of the airplane. Right now, the longest parts I know of are the horizontal stabilizer spars, which come in at about 11'6" each. I bought three twelve foot 2x4s and made a simple double-trough frame out of them. I used the plywood from the empennage delivery crate for the bottom of the troughs, and a four foot spare piece of 2x4 from the workbench assembly for the end caps. Drilled drain holes in one end and fashioned a couple of 2x4 blocks to allow for length customization, saving on chemical volume when working on parts shorter than the horizontal stabilizer spars.

Above is a picture of the finished dunk tank with the length blocks set at about six feet, just longer than the longest parts in both the rudder and vertical stabilizer. I then lined the active side of the tank with 4 mil plastic sheet and poked it down through the drain holes. I used a staple gun to temporarily keep the sheet in place. The dunk tank is ready to go! More pictures here.

The last thing I did was to rig up hooks and line for allowing the parts to air dry after the alumiprep and alodine washes are complete. Currently all of the parts for both the vertical stabilizer and rudder and hanging in the shop. The only thing I'm missing before I proceed with the chemistry is buckets to reclaim the used water and chemicals. Should be able to pick those up at the local hardware store. Then, it'll be time for SCIENCE!

31 Oct 2009

Got three sealable five-gallon buckets this morning, one for alodine, one for alumiprep, and one for distilled water. The Alodine comes by the gallon and gets mixed 1:2 with water, for a total of three gallons of solution. The Alumiprep also comes by the gallon and gets mixed 1:3 with water, for four gallons of solution. I pre-mixed these and labeled their respective buckets.

With the adjustable blocks in my dunk tank set at just over five feet (the length of the rudder spar), and each trough being six inches wide, three gallons was enough for an almost two inch deep pool of Alodine. I only used about three gallons of the Alumiprep as well.

The process of immersing the parts in each bath and then drying went surprisingly quickly. I was able to prep and alodine all of the parts for both the vertical stabilizer and rudder in about two hours including setup and cleanup. Also, this was my first time figuring out how everything would work, so I took a lot longer on some steps than I will require when I do this again for the horizontal stabilizer.

All of the parts now have that great golden finish to them and are ready for priming.

2 Nov 2009

Quite a bit has happened over the past two days. For starters, I primed all of the rudder and vertical stabilizer parts. Riveting together of the vertical stabilizer skeleton has also been started. Here's me about to stat priming all of the non-skin parts.

And here's all of the parts, including the skins, drying after being primed with Akzo 2-part epoxy primer.

(remainder of this entry dealt solely with vertical stabilizer construction)

6 Nov 2009

A couple of days ago I borrowed a heat gun and some RTV from Bob and finished off the wiring installs in the vertical stabilizer. The VS is now awaiting the grounding studs that are scheduled to arrive on Monday before I can start putting the skins on.

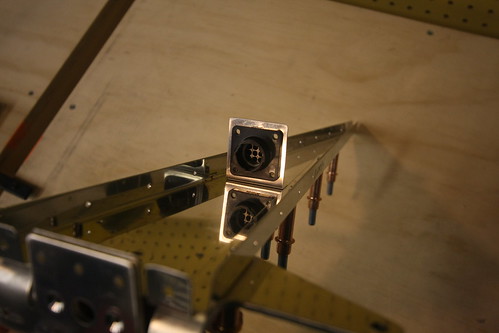

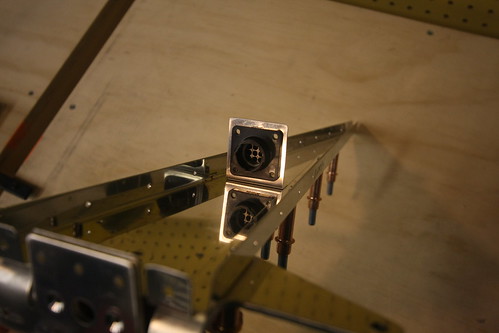

Tonight, in lieu of anything to do for the vertical stabilizer, I started the riveting steps on the rudder. The two spar doublers that suppor the hinge attach nutplates were the easiest. Everything could be squeezed and there were no problems. Here's the aft side of the upper doubler.

I need to add a ground post here as well, to be the counterpart to the one I'm adding to the VS. Since there was so much open space on this doubler, I figured I'd go ahead and rivet all existing holes and just add a hole between the two upper rivets for the post hardware. That step is now on hold awaiting the grounding studs arriving on Monday.

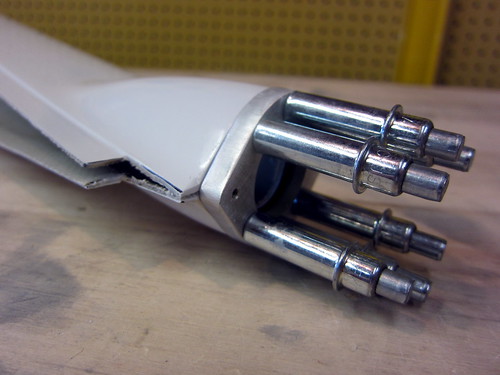

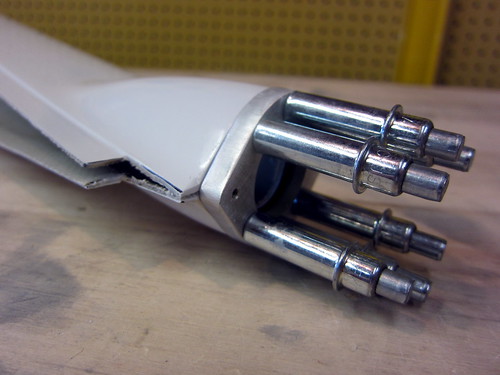

Riveted together the components of the bottom rudder rib, including the horn and the wiring customizations I made. This consists of a plastic bushing going through the rib to allow access to the interior of the rudder for the rudder trim wiring.

Here's a view of the bottom side of the completed lower rudder rib:

After that, the next step is the start back riveting the stiffeners onto the rudder skins. This went great, for awhile. I got awesome-looking rivets:

...and then I screwed it up really badly. I started going too quickly and didn't pay attention to where my steel plate was beneath the skin. I attempted to back rivet a rivet that was just barely off the edge of the plate. This achieved several very bad things in very short order. For starters, the skin got creased over the edge of the steel plate and is now decidedly unflat in the area of the rivet. The rivet hole is deformed and will require drilling out to a larger size. Finally, the edge of the back rivet set caught the edge of the steel plate, bending the spring collar and causing the moving parts of the rivet set to jam. That'll have to be replaced. Great.

Not sure if I can use this skin at all, now. My first impression is that the integrity of the skin is not compromised; it'll just look bad. I'm going to pass it by some other builders and see what they think before I proceed.

15 Nov 2009

Spent a few hours this afternoon getting some of the rudder parts riveted together. This had been on hold ever since I broke my back-rivet set last week. A replacement came in the mail on Friday and today I put it to use.

With all of the stiffeners attached to the skins, I moved on to the wire tie anchors needed to securely route wires from the lower fairing up to the rudder trim servo. These were the same anchor parts I used to pass wires and conduit through the lightening holes in the vertical stabilizer. In retrospect, I put them on the wrong side. I attached them to the left-side skin because that's what I had on the bench at the time. However, the right-side skin is where the rudder horn and lower rib get attached before the two sides are sewn up. If I had put them on the right side, I could run the entire wire bundle before beginning the pro-seal attachment activities (which are going to be hectic enough as it is with its limited pot life). Now, I'll have to do the wire-tieing as I go during the pro-seal ordeal.

Next I attached the rudder horn and lower rib to the right-side skin. This involved using the squeezer and the rivets came out very well. The only difficulty was the forward-most rivet, which the pneumatic squeezer can't reach. I'm not sure how to proceed on that one. With the body of the squeezer on the outside of the skin, the squeezer runs into the rudder horn. With the body of the squeezer on the inside of the skin, it runs into the opposite flange. I can't back-rivet it because the rivet gun will also run into the opposite flange. I can't use an offset set because they're all cupped. Have to think about this one. Perhaps someone makes an offset flush set?

With the horn attached (with all but one rivet), I went ahead and blind riveted the shear clips on. This was my first experience with blind rivets; they're really easy and fun to watch. It's a shame they aren't flush or structural.

16 Nov 2009

With where I left off last night, the rudder is now at the point in the instructions where the next step is to rivet the two sides together, rendering the insides largely inaccessible. With that in mind, it was time to take care of the internal customizations.

The first thing I did was put a circular plastic connector on the rudder trim servo wires. These are tiny 26awg wires which I had to buy special crimp pins for. The connector came out very well.

I was going to do the wiring harness that connects this CPC to the one riveted to the bottom of the lower rudder rib, but realized that I had neglected to get sockets appropriately sized for the 20awg wires I recently purchased for this harness. I went ahead and ordered the necessary parts (from mouser.com, of course) and the wiring harness will have to wait.

I also took a look at the static wick attachment options. There's going to have to be some rivet surgery; I should have thought about this before I riveted on the upper stiffeners. Each of the two wicks will need to have two nutplates installed on the left skin. The holes in the Dayton Granger 16165 wicks are sized for a #10 screw, so I ordered some AN525-10R6 and AN525-10R7 washer head screws from Aircraft Spruce in addition to some anchor nuts with elastic inserts. If I can fit these nutplates inside the very narrow trailing edge of the rudder, then my wicks will be removeable with a simple screwdriver when required for replacement or aesthetic snobbery. However, until this hardware shows up, the wicks are on hold as well.

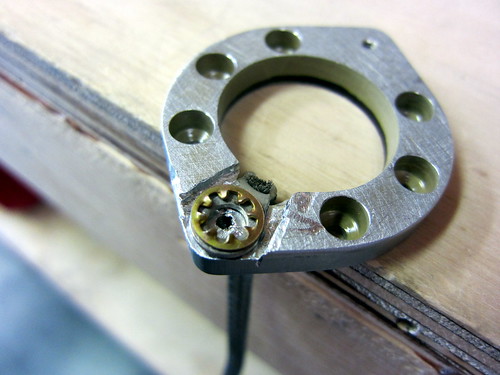

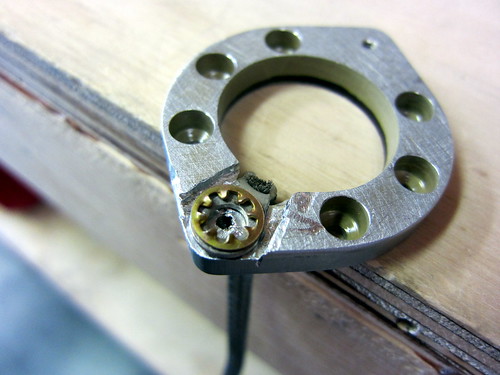

What I did have hardware for was the rudder bonding stud— the counterpart to the one I installed in the vertical stabilizer rear spar last week. This one is a clone of the VS stud and was prepared and installed in basically the same way. Here's a shot showing where I put it:

Unlike the VS stud, this one did not take the place of a rivet; I simply made a new 3/16" hole in between the upper most rivets on the doubler for the upper hinge nutplate on the rudder spar. On a whim, I measured the resistance between the top of the bonding stud and one of the adjacent rivets. It was 0.2 Ohms. From the top of the stud to the far end of the rudder spar was 4 Ohms.

19 Nov 2009

Today the pins and sockets which allow me to finish the rudder wiring arrived (along with some oops rivets to fix the two remaining biffed rivets on the VS). I bit the bullet and moved the wire tie anchors over from the left skin to the right. This allows me to pre-wire the rudder trim harness before having to button up the two sides of the rudder.

I stuffed a piece of 3/8" braided sheath through the snap bushing in the lower rudder rib, then fed the five 20awg wires through. The sheath was then wire-tied to the wire tie anchors in such a way that the sheath never touches metal anywhere (except on the free end, for now).

I put CPC pins on the lower end of each and fed them into the CPC that had been riveted into place when I fabricated the lower rib.

The upper end I am leaving unfinished until the time comes to actually wire up the servo. There will be an access plate cut into the left-side skin for getting at the servo, and through this hole I can finish the connector on the other end of this harness. In the meantime, I applied a pair of adhesive wire-tie anchors to the inside of the left-side skin, just aft of the spar. I'll tied the wires in place with these, keeping them out of the way for the final assembly of the rudder. When the time comes to cut rudder modifications into the rudder, I'll free the wires and run them through the lightening holes of the rudder to keep them out of the way.

The next task was to figure out how to attach the static wicks. I purchased some one- and two-lug anchor nuts with elastic inserts sized for a #10-32 thread. The #10 fits perfectly through the holes in the Dayton-Granger 16165 static wicks. Aircraft Spruce sells an AN525-10R7 washer-head screw that matches the #10-32 thread, has a head perfectly sized to hold the static wick down, and is exactly the right length so that the last thread protrudes out of the elastic insert but no further. This will allow me to put the nutplates as far aft as possible, where space comes at a premium. Here is an overhead view of the two nutplates I intend to use for the upper static wick just sitting in place and a wick next to them:

And here is the side view of the same anchor nuts showing how they fit within the rudder headroom next to the stiffener angle:

Note that these tests were done on the right-side skin because its stiffener was slightly taller at this end and was a more accurate representation of the available headroom. The wicks will actually be attached to the left-side skin, however, to add to the right rudder effect.

The next task will be to drill out the holes for the anchor nuts and countersink the rivet holes on the outside, allowing for AN4263-4 flush rivets to be back-riveted in.

22 Nov 2009

A couple days ago I finished up work on the rudder static wicks. First I drilled the holes out for the nutplates. I learned the hard way that the right order to do these in is to drill the large hole first, then attach the nutplate with a bolt and use the nutplate as a template for the two rivet holes. Trying to drill the smaller holes first, cleco them in, and then drill through the threaded part of the nutplate proved infeasible and I ended up having to enlarge the larger holes on one of the wick emplacements. Big holes first.

With the holes drilled and deburred, I set about countersinking the rivet holes on the outer side. They have to be flush because the flat static wick surface lays right across the top of them. Unfortunately, the skin is quite thin and the stiffener isn't exactly thick, either. Furthermore, with the stiffeners already in place, there wasn't a good way to get the holes level under my drill press. So I countersunk manually using my deburring tool. The countersinks aren't perfectly circular, but you have to get really close and be looking for it to notice that. I was able to back-rivet all of the rivets, except the spring sheath on my new back rivet set is made of poly instead of metal so it has to be thicker. The rivets adjacent to the threaded part of the anchor nuts ended up cleating a bit because the thicker sheath prevented the set from making full contact. This would be one advantage to the Isham Inc. backrivet set (the one I broke); it wouldn't have had this problem. I didn't worry too much about the cleated rivets, though, since these aren't structural and once the wicks are screwed in, they're redundant entirely.

With the anchor nuts attached, the static wicks screw right on from the outside. They're replaceable if needed, and removable if I want the plane to have cleaner lines for a photo op or something. Very happy with how this turned out.

Today, Bob came down and we spent a couple hours dealing with the first dreaded task of the entire plane: the rudder trailing edge. This, of course, involves the first usage of ProSeal (or its equivalent that Van's sold me) on the aircraft. This is nasty stuff; it sticks to everything and smells pretty bad to boot. I went through four pairs of nitrile gloves in a bit over an hour. I used a little hard plastic squeegee to apply the sealant to the extruded aluminum piece. Here's what it looked like once I got both sides applied and the edge piece layed on the skin.

Getting clecos to stay in the trailing edge holes proved to be really difficult. Certain holes just seemed to be slightly oversized from the dimpling or something and wouldn't hold a cleco. Others would hold a cleco in one orientation but not if it twisted. Others would hold some clecos but not others.

Bob held the skin back while I did all the internal blind rivets and added clecos to the trailing edge. I tied the rudder trim wire bundle to an adhesive wire tie anchor on the left skin to keep it out of the way of this process.

In the end, with the two skins attached via the stiffeners and the sealant, I was only able to get about 85% of the clecos into the trailing edge to stay.

I put a board on top of the skin to weigh it down and put some heavy stuff on top of that, but with all the missing clecos there were still some places where the trailing edges weren't as tight as I'd like. So Bob and I made a 9:30pm run to the grocery store and picked up 100 clothes pins for $4. They were small ones without a lot of clamping force, so I didn't have to worry about denting the aluminum or anything like that. But it was enough to bring the trailing edge skins down onto the extruded aluminum piece everywhere. We used a ton just to be safe:

Now I wait for two days while the sealant cures. This is convenient, because this is Thanksgiving week coming up and I have Wednesday, Thursday, and Friday off. So two day week, and a two day pause required for curing. As soon as my vacation rolls around, I'll be ready to work again (though my first cross country flight training is Wednesday morning, so the rudder work will be delayed a bit by that).

26 Nov 2009

Happy Thanksgiving. Before (and after) doing The Meal™, I got some work done on the rudder.

I didn't have an assistant to help me with bucked rivets, so I tried to do everything I could that involved blind rivets first. This began with the connections between the rudder spar and the shear clips. However, before I did those I wanted to do some final tending on the rudder trim wire harness. I put a final wire tie into one of the adhesive anchors on the inside of the left-side skin.

Then I put the spar in place and routed the wire harness through the nearest lightening hole. The idea is that the wire harness will be out of the rudder trim bay when I go to make the cuts for the access panel and the trim tab itself. For the time being, I'll just run the wires down the forward side of the spar, between the spar and the rounded leading edge. Once the cuts are made in the trim area, I'll pull the wire harness back through the lightening hole and tend the end. With the wiring taken care of (for now), the spar's blind rivets went really quickly.

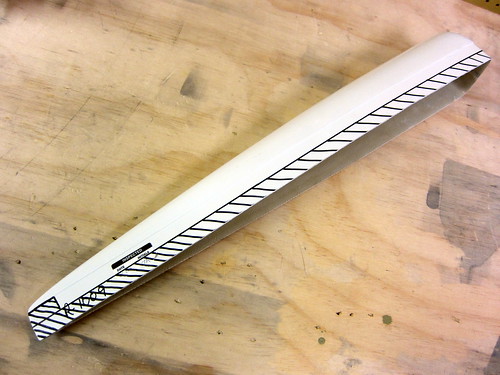

With that, the only remaining task on the rudder that I could accomplish without an assistant was riveting the trailing edge. I had been somewhat apprehensive about starting this because there's a lot of talk on builder's logs about it being 1) difficult and 2) critical. I decided to go with a variation of the method described on Tim Olson's website—to make a long back-rivet plate out of a 6' piece of 2"x2" angle iron and cleco the rudder to it.

I started by screwing the angle iron into my work bench such that the top surfaces of both were flush. Then I used the elevator trailing edge extrusion as a template to drill holes into the top surface of the angle iron. I drilled every 10th hole plus one at the end so that there would be clecos at each end of the rudder, for a total of 7 clecos holding the rudder onto the plate.

With the holes in place, I put rivets into every other hole of the trailing edge, secured them with rivet tape, then flipped the rudder over and attached it to the angle iron with clecos.

I just used a flush set on the shop side of the rivets and they came out OK. With the first side's rivets complete, I removed the clecos, put rivets in the remaining holes (with the exception of the seven cleco holes), taped them, flipped the rudder over, and back-riveted these new rivets. This left just the seven holes to be done without the aid of cleco attachment to the back-rivet plate. This was not a problem and they didn't introduce any bend to the trailing edge.

All-in-all, the trailing edge was exceptionally easy with this method and I got a great-looking, unwavy, un-bend trailing edge out of it. Highly recommended for future builders.

28 Nov 2009

Big day for the rudder.

Nina gave me a hand in the morning bucking the rivets connecting the skins to the rudder spar. We also finished off the lower rib flange rivets and the rivets attaching the two halves of the upper rib. With that, it was time to do the rudder counterweight.

The lead weight was clamped into place and the skins bent around it by hand. After that, a bending jig was assembled out of blocks of wood and C-clamps.

From there, the skins are bent into tight angles so that they will envelope the lead brick. Before inserting the lead brick, I added a couple of small customizations not given in the plans. First, I covered the lead brick's edges in a ring of electrical tape so that there will be no exposed lead in the final part.

The other minor change was to prime the piece of skin that is covered by the other side skin on the forward side of the lead brick. I scuffed this area with scotchbrite then used a Krylon spraycan primer.

Once these modifications were made, the lead brick was attached to the rudder permanently.

With the counterweight complete, it was time to close up the leading edge of the skins. However, before this was done I had to attach the bonding strap to the my custom bonding stud. This was a straightforward crimp of the strap into a ring terminal, and adding a castle nut and cotter pin to hold it in place.

The leading edge skin tabs were rolled using a 1" diameter broom handle. The section of the skin that gets overlapped was again treated with primer, just as was done for the counterweight skins.

Once all the match drilling and priming was complete, the leading edge was cleco'd up again and then the blind rivets were put in place. This is a quick operation.

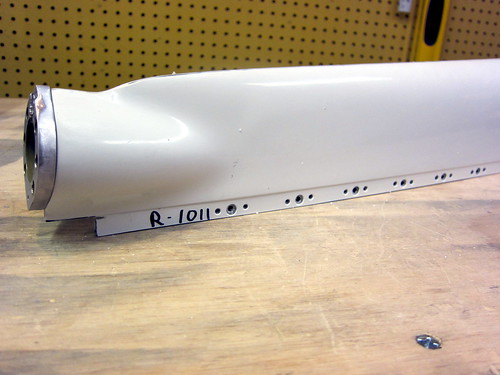

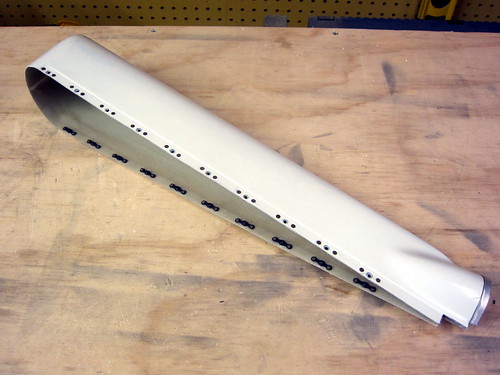

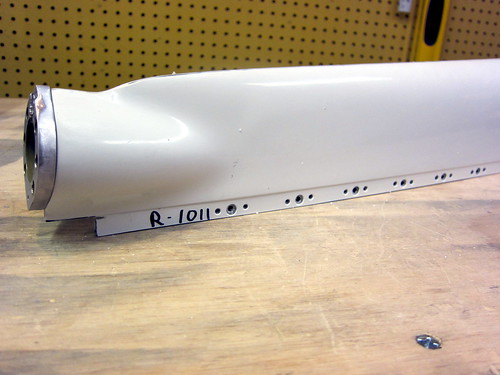

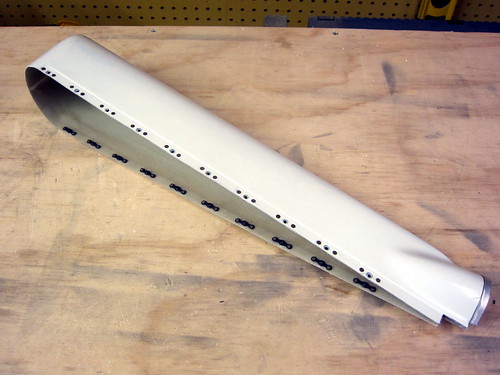

With that, the rudder as specified in Section 7 of the plans was complete.

I placed the rudder down next to the vertical stabilizer to check the fit. Unfortunately, the VS bonding stud runs into the leading edge curve of the rudder. I'll have to cut off a bit of the upper leading edge of the rudder to make room for this, but that's not a terribly difficult modification.

Of course I haven't made the mechanical modifications for the rudder trim system either. This will be a major undertaking and entirely off the reservation as far as the plans are concern. However, I do not need to make this modification immediately; I'll probably save it for some time when I'm waiting for a future kit to ship or for more money to be made so that I can buy the next kit. Rudder trim is to be continued; for now, the rudder is "done."

29 Nov 2009

The first thing I did today was finish up a few remaining tasks on the vertical stabilizer and rudder. The vertical stabilizer just needed a couple of rivets put in. They were at the bottom of the foreward spar and I had biffed them the first time through, then really mangled the holes trying to drill them out. My solution was to get some big 3/16" AN470 rivets to fill the holes. I drilled out the new big holes with my right-angle drill kit, inserted the big fatty rivets, and drove them home with my 3x rivet gun. No problem. Aside from being huge, they look great. They're probably stronger than the original rivet, so as far as I'm concerned its an improvement. I now pronounce the vertical stabilizer complete until Section 12 (fiberglass fairings) comes along. I taped up the holes in the VS to prevent bugs from getting in, and put it out in the shed for long-term storage.

Next I put a few last touches on the rudder. First I cut a small section out of the leading edge above the upper hinge opening to make clearance for the vertical stabilizer's bonding stud.

The cut was made with a dremel cutoff wheel and was straightforward. I cleaned up the edges with a file and an edge deburring tool. As a result of the cut, the rudder's bonding stud is now directly accessible, which may aid in future inspections and maintenance, though the whole point of not having a more compact bonding attachment on the vertical stabilizer was because the rudder attachment would be harder to reach. Now they're both about the same difficulty to work with... so I'm not sure if there would be a better arrangement if the assumption was made up front that this cut would be made.

Something to think about for future builders wanting to do some bond strap work, I suppose. Regardless, I'm happy with how it turned out. The VS and rudder fit together perfectly now.

I taped up the holes in the rudder for the same reason as I had in the VS, and while doing so found three rivets at the base of the rudder spar that I had overlooked yesterday. Whoops! Not a problem, they were still fully accessible so I just squeezed them in and that was that. The rudder is now complete until Section 12 (or until I decide to make the rudder trim cuts, whichever comes first).

17 Aug 2010

Time for the first of the rudder fairings. The top rudder fairing is nice in that it requires no major modifications and won't be removable. For some reason, the fairing had a 1.25" flange on it as upposed to the 0.5" flange that the other fairing pieces had. So I had to make a big cut in this one to get it to fit in its place.

After trimming all of that off, I did a test fit only to find that the small forward flange on the fairing would run into the lead counterweight brick before the flange was fully inside the rudder skins. So I marked off another small bit to dremel off of the front flange.

With that second trim cut made, the fairing fit inside the counterweight arm of the rudder very nicely.

There were only two problem areas. First, the notch I made at the aft point for the trailing edge extrusion went too high by accident. I'll have to fill that in with microballoons or something. Also, the trailing point of the fairing falls about 1/16" short of the trailing edge of the skin. I may just file the skin corner down to be flush and call it good.

The second problem area was at the front of the counterweight arm, where I had previously bent the skins down around the lead brick. The bend has a bit of an overshoot that I hadn't previously noticed. But against the smooth line of the fairing, it's pretty obvious:

Most of that I was able to beat down with the hand seamer. The rest I'll just fill with microballoons during the blend process.

Overall, this fairing has been the best-fitting so far. The joint between the skin and fairing is really flush and smooth almost all the way around.

This fairing is complete until the filling/blending step occurrs (and that could be some time off). Next up will be the lower rudder fairing, which entails wiring up the tail light... but that's for another night.

18 Aug 2010

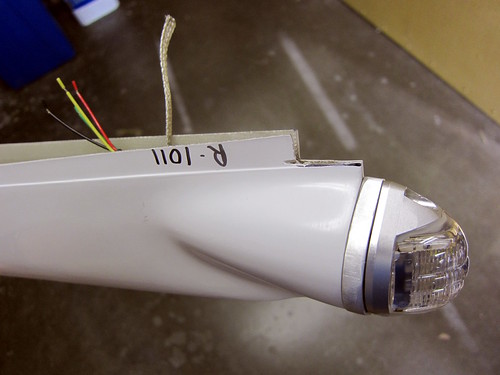

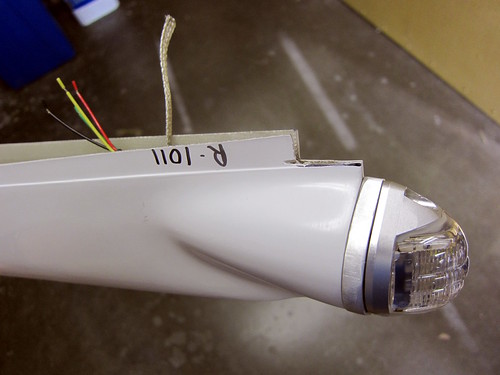

Started work on the bottom rudder fairing. This piece will take a fair amount of time because I'm making it removable, which isn't in the plans, and I'm adding a tail light attachment plate (from Cleaveland Tool). First up was the usual trim cuts to make everything fit. Here they are marked, with the attachment plate laying nearby:

The trailing edge notch I made with the dremel cutoff wheel like usual. The tail light hole I made by drilling successively larger holes until I had a 0.5" hole, then I went in there with a dremel sanding drum to finish it out. Next, I match-drilled the attachment plate to the aft face of the fairing:

The next bit required some creativity. AeroLEDs, the maker of the SunTail LED NAV/Strobe light that I'm using in the rudder, recently released a recommendation that the metal body of the light be grounded in addition to the black ground wire coming out of the back. Apparently this will help quell noise from the strobe light getting into the headsets and interfering with navigation equipment.

So how should I attach a ground to the tail light chassis? The attachment plate would be a good start, but it is just attached to fiberglass, so I need a bonding strap. I initially wanted to attach a small plate to the back of one of the pop rivets that holds the plate to the fairing, but there isn't enough room in there to do this. What I ended up with was milling a notch into the aft face of the plate big enough to get a ring terminal and a star washer around one of the light attach screws. Like this:

This way, when the tail light is screwed on, it presses the star washer down, causing good electrical contact between the plate, the light, and the bonding strap. The result (sans fairing) looks like this:

Next, it was time to rivet the plate to the fairing. There are six countersunk holes in the plate made for CS4-4 pop rivets, but the head of my pop riveter wouldn't fit down into the holes. So I had to fabricate a spacer. I was going to use the bushing that was previously used as a drill guard when drilling the elevator control horns, but it is steel and my bandsaw wouldn't cut it. Instead, I just lopped the ring off of a ring terminal and used the un-crimped shank.

This worked great, except that the last rivet I put in cracked the gel coat adjacent to the plate. Boo. It turns out that the fiberglass had bubbled up behind this spot so there was nothing supporting the non-structural gel coat, so it was doomed to fail. No biggy, I'll just blend over this when I blend the plate to the fairing later.

Other than the crack, I'm really happy with how the tail light install came out. It looks great test-assembled!

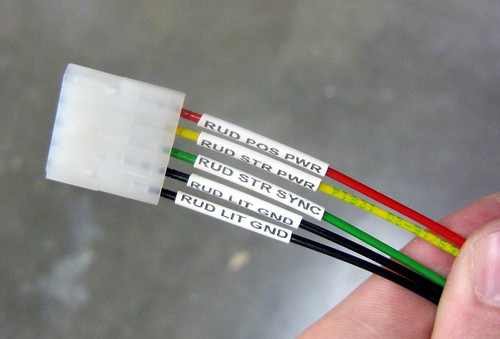

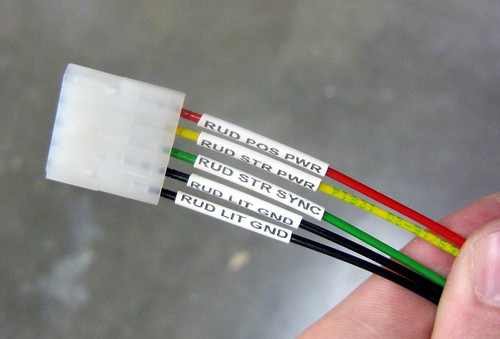

I went ahead and put the (provided) molex connector on the tail light wires, and wired an extra ground wire into the usually empty fifth pin. I need to get a pair of faston connectors to connect the other end of the bonding strap to the spare ground wire, then the tail light will be complete.

Continuing on with the lower rudder fairing, I match-drilled all of the holes from the rudder skin into the fairing, but rather than stopping at #30 for CS4-4 pop rivets, I am going to #27 for #6 screws. I want my lower rudder fairing to be removable so I can gain access to the electrical connectors in there. This means that I'll need nutplates behind each hole, so I used a nutplate as a template and drilled rivet holes next to each screw hole. Countersinking these was straightforward. I also went ahead and dimpled the holes in the rudder skin for #6 screw heads.

All that is left for this piece is to put nutplates on it. I'm leaving that for another day as it's time for bed.

20 Aug 2010

Got the nutplates put onto the bottom rudder fairing, rendering it complete aside from some minor blending to do around the tail light mount plate and its associated crack.

I had planned on using AN507-C632R8 stainless screws to attach the fairing to the rudder, but they are too long for the aft-most holes:

I'll probably replace these two with -6R6, or possibly just replace them all with the shorter bolts so that I have homogeniety of parts.

With the fairing done, I went ahead and finished off the tail light wiring. I spent some time on this and made it look really good. Partially because I want my electrical system to be really solid, but also because it gave me a chance to mess with my new heat gun and heat shrink label printer.

I spliced the two ground wires from the tail light into a single wire going into the rudder CPC. There shouldn't be any current off the chassis ground; it's just a shield wire, essentially. So there was no need to upsize the wire gauge. I put heat shrink over the splice, then wrapped the entire wire harness in abrasion-resistant weave, and heat shrunk the ends. The result looks like this:

Next, I knocked the pins from rudder trim out of the CPC so that I could thread them through a strain relief clamp. Both wire harnesses were put through the clamp and everything was tightened down. The result looks professional and doesn't interfere with the nearby AN507 screw.

I left enough slack between the CPC and the tail light Molex connector that I can remove the fairing without disconnecting the tail light (as seen above) or I can pull the tail light off and get to the Molex connector without taking the fairing off.

With that, the rudder is finished other than blending, trim, and paint.

Time invested on this sub-assembly: 50 hours (46 by me)

I'm planning on adding a rudder trim modification to the rudder as well as an LED NAV/strobe light at the back of the lower fairing. There will therefore be some wiring runs within the rudder and some means of routing wire from the rudder, through the bottom of the vertical stabilizer rear bulkhead, and into the aft end of the tailcone.

For the trim modification, I'll be using a Ray Allen T2-7A servo to drive a cut-out section of trailing edge. I like the aesthetics of this style of rudder trim more than the Tim Olson style hinge-on-trailing-edge, though it does require considerably more work.

Updates regarding the rudder

17 Oct 2009The vertical stabilizer parts are all fabricated and awaiting primer, but I need to get some long lumber to make my part prep tanks and I don't have access to my truck this week. So I shelved the VS parts and started on the rudder. No marathon sessions this week, just an hour here and there. Total of about four hours over various lunch breaks and after dinner cleco sessions.

The first step was to lay out all of the rudder parts for a group shot. The only thing missing here is the electrical connectors, wire, and skins.

Just like with the vertical stabilizer, the rudder starts out with some bandsaw cuts. In this case, a bunch of smaller pieces are joined together with little tabs for ease of manufacturing. It was a reasonably quick piece of work to turn seven identical pieces of angle aluminum and three other punched sheets into these 25 parts:

The pieces for the rudder went together astonishingly quickly; it didn't take long at all to get to the point where I was putting skins on for the first time.

The last thing I did before leaving town for the weekend was put the second skin on in preparation for final drilling.

At this point, I'll probably just finish up with the final drilling and dimpling of all rudder pieces and do all of the priming of both VS and rudder together in one shot to minimize painting overhead.

19 Oct 2009

Over the last two days, I've put in four more hours preparing parts for the rudder. Despite the relatively small number of hours, some significant work was accomplished.

I match drilled all of the holes in the rudder skin, then disassembled the rudder completely and deburred all of the skeleton parts and dimpled the ribs, stiffeners, and spar. I also made some changes for the planned electrical wiring within the rudder.

The plan is to have a wire bundle hanging out the back end of the tailcone beneath the bottom of the lower rudder rib but above the bottom of the lower rudder fairing. A hole will be made in the lower fairing that will allow this cable to enter the fairing during normal operation. The wire will connect to a circular plastic connector attached to the bottom of the lower rudder rib, and from there the cables will split into two groups. The first group will just connect to the tail light at the aft end of the fairing. The second group will pass through a snap bushing in the lower rib and then travel up through three of the stiffeners to the area where the rudder trim modification will eventually be made.

For the time being, the wire bundle will just end in another CPC between the C and D stiffeners. I'll make the cuts for the rudder trim after the rudder has been riveted together. In order to safely pass the wires through the triangular holes in the stiffeners, I drilled out one of the unused holes in each of the left side stiffeners to which I plan to rivet some of the lightening hole wire tie attach brackets. These should keep the wires out of contact with the metal. Thus, the modifications to the three stiffeners were composed simply of final drilling three holes.

The lower rib was a bit more complex. First I fabricated a small angle flange to attach the CPC to.

This, in turn, will get riveted to the bottom side of the lower rib.

Finally, a 3/8" hole was drilled aft of the CPC flange in the lower rib for the snap bushing through which the trim servo wires will pass. That's it for parts fabrication for the rudder wiring. I disassembled the lower rib and modified flanges, deburred everything, and dimpled them where appropriate.

All that remains before priming of the rudder is to make the bend at the trailing edges of the skins, deburr the skins, and dimple the skins.

20 Oct 2009

Nothing momentus happened today; spent about an hour deburring both sides of both rudder skins. Need to figure out the right way to make the bend in the trailing edge before I proceed to dimpling.

29 Oct 2009

A bunch of random things have occurred in the last week. After reading up on other builders websites, I determined that I wouldn't be making the bend in the trailing edge of the rudder at all. I'll be using the angle iron backrivet technique and tank sealant to ensure a good bond at the trailing edge.

Making this decision cleared me to finish up the rudder skins. I removed the vinyl coating from the rivet lines and Bob assisted with the dimpling of all the holes. The next step on the skins will be to scuff the inner surface, clean it, and then prime it.

I spent a lot of time thinking about how to do bond straps between the rudder and vertical stab. I was unable to find appropriate ring terminals, bolts, washers, and nuts in aluminum... so I've decided to use passivated cadmium-plated steel hardware instead and hope for the best. I ordered some candidate pieces from Aircraft Spruce and they look like they might work. I also ordered hardware for making the vertical stabilizer and lower rudder fairings removable via nutplates. Unfortunately I based my parts decisions here on another builder's website who had a typo in their part numbers! I ordered thirty K1000-6 nutplates instead of K1000-06 nutplates without checking the bolt size vs. nutplate size. That's a $50 oops! Reordered the correct nutplates from Van's. They'll be here long before I'm ready for them. If anyone needs any of the huge K1000-6 nutplates... let me know.

The other major accomplishment of this week was building the dunk tank for doing alumiprep and alodine chemistry on the long thin parts of the aircraft. I didn't want to have to build more than one of these, so I made it really long to accomodate the longest pieces of the airplane. Right now, the longest parts I know of are the horizontal stabilizer spars, which come in at about 11'6" each. I bought three twelve foot 2x4s and made a simple double-trough frame out of them. I used the plywood from the empennage delivery crate for the bottom of the troughs, and a four foot spare piece of 2x4 from the workbench assembly for the end caps. Drilled drain holes in one end and fashioned a couple of 2x4 blocks to allow for length customization, saving on chemical volume when working on parts shorter than the horizontal stabilizer spars.

Above is a picture of the finished dunk tank with the length blocks set at about six feet, just longer than the longest parts in both the rudder and vertical stabilizer. I then lined the active side of the tank with 4 mil plastic sheet and poked it down through the drain holes. I used a staple gun to temporarily keep the sheet in place. The dunk tank is ready to go! More pictures here.

The last thing I did was to rig up hooks and line for allowing the parts to air dry after the alumiprep and alodine washes are complete. Currently all of the parts for both the vertical stabilizer and rudder and hanging in the shop. The only thing I'm missing before I proceed with the chemistry is buckets to reclaim the used water and chemicals. Should be able to pick those up at the local hardware store. Then, it'll be time for SCIENCE!

31 Oct 2009

Got three sealable five-gallon buckets this morning, one for alodine, one for alumiprep, and one for distilled water. The Alodine comes by the gallon and gets mixed 1:2 with water, for a total of three gallons of solution. The Alumiprep also comes by the gallon and gets mixed 1:3 with water, for four gallons of solution. I pre-mixed these and labeled their respective buckets.

With the adjustable blocks in my dunk tank set at just over five feet (the length of the rudder spar), and each trough being six inches wide, three gallons was enough for an almost two inch deep pool of Alodine. I only used about three gallons of the Alumiprep as well.

The process of immersing the parts in each bath and then drying went surprisingly quickly. I was able to prep and alodine all of the parts for both the vertical stabilizer and rudder in about two hours including setup and cleanup. Also, this was my first time figuring out how everything would work, so I took a lot longer on some steps than I will require when I do this again for the horizontal stabilizer.

All of the parts now have that great golden finish to them and are ready for priming.

2 Nov 2009

Quite a bit has happened over the past two days. For starters, I primed all of the rudder and vertical stabilizer parts. Riveting together of the vertical stabilizer skeleton has also been started. Here's me about to stat priming all of the non-skin parts.

And here's all of the parts, including the skins, drying after being primed with Akzo 2-part epoxy primer.

(remainder of this entry dealt solely with vertical stabilizer construction)

6 Nov 2009

A couple of days ago I borrowed a heat gun and some RTV from Bob and finished off the wiring installs in the vertical stabilizer. The VS is now awaiting the grounding studs that are scheduled to arrive on Monday before I can start putting the skins on.

Tonight, in lieu of anything to do for the vertical stabilizer, I started the riveting steps on the rudder. The two spar doublers that suppor the hinge attach nutplates were the easiest. Everything could be squeezed and there were no problems. Here's the aft side of the upper doubler.

I need to add a ground post here as well, to be the counterpart to the one I'm adding to the VS. Since there was so much open space on this doubler, I figured I'd go ahead and rivet all existing holes and just add a hole between the two upper rivets for the post hardware. That step is now on hold awaiting the grounding studs arriving on Monday.

Riveted together the components of the bottom rudder rib, including the horn and the wiring customizations I made. This consists of a plastic bushing going through the rib to allow access to the interior of the rudder for the rudder trim wiring.

Here's a view of the bottom side of the completed lower rudder rib:

After that, the next step is the start back riveting the stiffeners onto the rudder skins. This went great, for awhile. I got awesome-looking rivets:

...and then I screwed it up really badly. I started going too quickly and didn't pay attention to where my steel plate was beneath the skin. I attempted to back rivet a rivet that was just barely off the edge of the plate. This achieved several very bad things in very short order. For starters, the skin got creased over the edge of the steel plate and is now decidedly unflat in the area of the rivet. The rivet hole is deformed and will require drilling out to a larger size. Finally, the edge of the back rivet set caught the edge of the steel plate, bending the spring collar and causing the moving parts of the rivet set to jam. That'll have to be replaced. Great.

Not sure if I can use this skin at all, now. My first impression is that the integrity of the skin is not compromised; it'll just look bad. I'm going to pass it by some other builders and see what they think before I proceed.

15 Nov 2009

Spent a few hours this afternoon getting some of the rudder parts riveted together. This had been on hold ever since I broke my back-rivet set last week. A replacement came in the mail on Friday and today I put it to use.

With all of the stiffeners attached to the skins, I moved on to the wire tie anchors needed to securely route wires from the lower fairing up to the rudder trim servo. These were the same anchor parts I used to pass wires and conduit through the lightening holes in the vertical stabilizer. In retrospect, I put them on the wrong side. I attached them to the left-side skin because that's what I had on the bench at the time. However, the right-side skin is where the rudder horn and lower rib get attached before the two sides are sewn up. If I had put them on the right side, I could run the entire wire bundle before beginning the pro-seal attachment activities (which are going to be hectic enough as it is with its limited pot life). Now, I'll have to do the wire-tieing as I go during the pro-seal ordeal.

Next I attached the rudder horn and lower rib to the right-side skin. This involved using the squeezer and the rivets came out very well. The only difficulty was the forward-most rivet, which the pneumatic squeezer can't reach. I'm not sure how to proceed on that one. With the body of the squeezer on the outside of the skin, the squeezer runs into the rudder horn. With the body of the squeezer on the inside of the skin, it runs into the opposite flange. I can't back-rivet it because the rivet gun will also run into the opposite flange. I can't use an offset set because they're all cupped. Have to think about this one. Perhaps someone makes an offset flush set?

With the horn attached (with all but one rivet), I went ahead and blind riveted the shear clips on. This was my first experience with blind rivets; they're really easy and fun to watch. It's a shame they aren't flush or structural.

16 Nov 2009

With where I left off last night, the rudder is now at the point in the instructions where the next step is to rivet the two sides together, rendering the insides largely inaccessible. With that in mind, it was time to take care of the internal customizations.

The first thing I did was put a circular plastic connector on the rudder trim servo wires. These are tiny 26awg wires which I had to buy special crimp pins for. The connector came out very well.

I was going to do the wiring harness that connects this CPC to the one riveted to the bottom of the lower rudder rib, but realized that I had neglected to get sockets appropriately sized for the 20awg wires I recently purchased for this harness. I went ahead and ordered the necessary parts (from mouser.com, of course) and the wiring harness will have to wait.

I also took a look at the static wick attachment options. There's going to have to be some rivet surgery; I should have thought about this before I riveted on the upper stiffeners. Each of the two wicks will need to have two nutplates installed on the left skin. The holes in the Dayton Granger 16165 wicks are sized for a #10 screw, so I ordered some AN525-10R6 and AN525-10R7 washer head screws from Aircraft Spruce in addition to some anchor nuts with elastic inserts. If I can fit these nutplates inside the very narrow trailing edge of the rudder, then my wicks will be removeable with a simple screwdriver when required for replacement or aesthetic snobbery. However, until this hardware shows up, the wicks are on hold as well.

What I did have hardware for was the rudder bonding stud— the counterpart to the one I installed in the vertical stabilizer rear spar last week. This one is a clone of the VS stud and was prepared and installed in basically the same way. Here's a shot showing where I put it:

Unlike the VS stud, this one did not take the place of a rivet; I simply made a new 3/16" hole in between the upper most rivets on the doubler for the upper hinge nutplate on the rudder spar. On a whim, I measured the resistance between the top of the bonding stud and one of the adjacent rivets. It was 0.2 Ohms. From the top of the stud to the far end of the rudder spar was 4 Ohms.

19 Nov 2009

Today the pins and sockets which allow me to finish the rudder wiring arrived (along with some oops rivets to fix the two remaining biffed rivets on the VS). I bit the bullet and moved the wire tie anchors over from the left skin to the right. This allows me to pre-wire the rudder trim harness before having to button up the two sides of the rudder.

I stuffed a piece of 3/8" braided sheath through the snap bushing in the lower rudder rib, then fed the five 20awg wires through. The sheath was then wire-tied to the wire tie anchors in such a way that the sheath never touches metal anywhere (except on the free end, for now).

I put CPC pins on the lower end of each and fed them into the CPC that had been riveted into place when I fabricated the lower rib.

The upper end I am leaving unfinished until the time comes to actually wire up the servo. There will be an access plate cut into the left-side skin for getting at the servo, and through this hole I can finish the connector on the other end of this harness. In the meantime, I applied a pair of adhesive wire-tie anchors to the inside of the left-side skin, just aft of the spar. I'll tied the wires in place with these, keeping them out of the way for the final assembly of the rudder. When the time comes to cut rudder modifications into the rudder, I'll free the wires and run them through the lightening holes of the rudder to keep them out of the way.

The next task was to figure out how to attach the static wicks. I purchased some one- and two-lug anchor nuts with elastic inserts sized for a #10-32 thread. The #10 fits perfectly through the holes in the Dayton-Granger 16165 static wicks. Aircraft Spruce sells an AN525-10R7 washer-head screw that matches the #10-32 thread, has a head perfectly sized to hold the static wick down, and is exactly the right length so that the last thread protrudes out of the elastic insert but no further. This will allow me to put the nutplates as far aft as possible, where space comes at a premium. Here is an overhead view of the two nutplates I intend to use for the upper static wick just sitting in place and a wick next to them:

And here is the side view of the same anchor nuts showing how they fit within the rudder headroom next to the stiffener angle:

Note that these tests were done on the right-side skin because its stiffener was slightly taller at this end and was a more accurate representation of the available headroom. The wicks will actually be attached to the left-side skin, however, to add to the right rudder effect.

The next task will be to drill out the holes for the anchor nuts and countersink the rivet holes on the outside, allowing for AN4263-4 flush rivets to be back-riveted in.

22 Nov 2009

A couple days ago I finished up work on the rudder static wicks. First I drilled the holes out for the nutplates. I learned the hard way that the right order to do these in is to drill the large hole first, then attach the nutplate with a bolt and use the nutplate as a template for the two rivet holes. Trying to drill the smaller holes first, cleco them in, and then drill through the threaded part of the nutplate proved infeasible and I ended up having to enlarge the larger holes on one of the wick emplacements. Big holes first.

With the holes drilled and deburred, I set about countersinking the rivet holes on the outer side. They have to be flush because the flat static wick surface lays right across the top of them. Unfortunately, the skin is quite thin and the stiffener isn't exactly thick, either. Furthermore, with the stiffeners already in place, there wasn't a good way to get the holes level under my drill press. So I countersunk manually using my deburring tool. The countersinks aren't perfectly circular, but you have to get really close and be looking for it to notice that. I was able to back-rivet all of the rivets, except the spring sheath on my new back rivet set is made of poly instead of metal so it has to be thicker. The rivets adjacent to the threaded part of the anchor nuts ended up cleating a bit because the thicker sheath prevented the set from making full contact. This would be one advantage to the Isham Inc. backrivet set (the one I broke); it wouldn't have had this problem. I didn't worry too much about the cleated rivets, though, since these aren't structural and once the wicks are screwed in, they're redundant entirely.

With the anchor nuts attached, the static wicks screw right on from the outside. They're replaceable if needed, and removable if I want the plane to have cleaner lines for a photo op or something. Very happy with how this turned out.

Today, Bob came down and we spent a couple hours dealing with the first dreaded task of the entire plane: the rudder trailing edge. This, of course, involves the first usage of ProSeal (or its equivalent that Van's sold me) on the aircraft. This is nasty stuff; it sticks to everything and smells pretty bad to boot. I went through four pairs of nitrile gloves in a bit over an hour. I used a little hard plastic squeegee to apply the sealant to the extruded aluminum piece. Here's what it looked like once I got both sides applied and the edge piece layed on the skin.

Getting clecos to stay in the trailing edge holes proved to be really difficult. Certain holes just seemed to be slightly oversized from the dimpling or something and wouldn't hold a cleco. Others would hold a cleco in one orientation but not if it twisted. Others would hold some clecos but not others.

Bob held the skin back while I did all the internal blind rivets and added clecos to the trailing edge. I tied the rudder trim wire bundle to an adhesive wire tie anchor on the left skin to keep it out of the way of this process.

In the end, with the two skins attached via the stiffeners and the sealant, I was only able to get about 85% of the clecos into the trailing edge to stay.

I put a board on top of the skin to weigh it down and put some heavy stuff on top of that, but with all the missing clecos there were still some places where the trailing edges weren't as tight as I'd like. So Bob and I made a 9:30pm run to the grocery store and picked up 100 clothes pins for $4. They were small ones without a lot of clamping force, so I didn't have to worry about denting the aluminum or anything like that. But it was enough to bring the trailing edge skins down onto the extruded aluminum piece everywhere. We used a ton just to be safe:

Now I wait for two days while the sealant cures. This is convenient, because this is Thanksgiving week coming up and I have Wednesday, Thursday, and Friday off. So two day week, and a two day pause required for curing. As soon as my vacation rolls around, I'll be ready to work again (though my first cross country flight training is Wednesday morning, so the rudder work will be delayed a bit by that).

26 Nov 2009

Happy Thanksgiving. Before (and after) doing The Meal™, I got some work done on the rudder.

I didn't have an assistant to help me with bucked rivets, so I tried to do everything I could that involved blind rivets first. This began with the connections between the rudder spar and the shear clips. However, before I did those I wanted to do some final tending on the rudder trim wire harness. I put a final wire tie into one of the adhesive anchors on the inside of the left-side skin.

Then I put the spar in place and routed the wire harness through the nearest lightening hole. The idea is that the wire harness will be out of the rudder trim bay when I go to make the cuts for the access panel and the trim tab itself. For the time being, I'll just run the wires down the forward side of the spar, between the spar and the rounded leading edge. Once the cuts are made in the trim area, I'll pull the wire harness back through the lightening hole and tend the end. With the wiring taken care of (for now), the spar's blind rivets went really quickly.

With that, the only remaining task on the rudder that I could accomplish without an assistant was riveting the trailing edge. I had been somewhat apprehensive about starting this because there's a lot of talk on builder's logs about it being 1) difficult and 2) critical. I decided to go with a variation of the method described on Tim Olson's website—to make a long back-rivet plate out of a 6' piece of 2"x2" angle iron and cleco the rudder to it.

I started by screwing the angle iron into my work bench such that the top surfaces of both were flush. Then I used the elevator trailing edge extrusion as a template to drill holes into the top surface of the angle iron. I drilled every 10th hole plus one at the end so that there would be clecos at each end of the rudder, for a total of 7 clecos holding the rudder onto the plate.

With the holes in place, I put rivets into every other hole of the trailing edge, secured them with rivet tape, then flipped the rudder over and attached it to the angle iron with clecos.

I just used a flush set on the shop side of the rivets and they came out OK. With the first side's rivets complete, I removed the clecos, put rivets in the remaining holes (with the exception of the seven cleco holes), taped them, flipped the rudder over, and back-riveted these new rivets. This left just the seven holes to be done without the aid of cleco attachment to the back-rivet plate. This was not a problem and they didn't introduce any bend to the trailing edge.

All-in-all, the trailing edge was exceptionally easy with this method and I got a great-looking, unwavy, un-bend trailing edge out of it. Highly recommended for future builders.

28 Nov 2009

Big day for the rudder.

Nina gave me a hand in the morning bucking the rivets connecting the skins to the rudder spar. We also finished off the lower rib flange rivets and the rivets attaching the two halves of the upper rib. With that, it was time to do the rudder counterweight.

The lead weight was clamped into place and the skins bent around it by hand. After that, a bending jig was assembled out of blocks of wood and C-clamps.

From there, the skins are bent into tight angles so that they will envelope the lead brick. Before inserting the lead brick, I added a couple of small customizations not given in the plans. First, I covered the lead brick's edges in a ring of electrical tape so that there will be no exposed lead in the final part.

The other minor change was to prime the piece of skin that is covered by the other side skin on the forward side of the lead brick. I scuffed this area with scotchbrite then used a Krylon spraycan primer.

Once these modifications were made, the lead brick was attached to the rudder permanently.

With the counterweight complete, it was time to close up the leading edge of the skins. However, before this was done I had to attach the bonding strap to the my custom bonding stud. This was a straightforward crimp of the strap into a ring terminal, and adding a castle nut and cotter pin to hold it in place.

The leading edge skin tabs were rolled using a 1" diameter broom handle. The section of the skin that gets overlapped was again treated with primer, just as was done for the counterweight skins.

Once all the match drilling and priming was complete, the leading edge was cleco'd up again and then the blind rivets were put in place. This is a quick operation.

With that, the rudder as specified in Section 7 of the plans was complete.

I placed the rudder down next to the vertical stabilizer to check the fit. Unfortunately, the VS bonding stud runs into the leading edge curve of the rudder. I'll have to cut off a bit of the upper leading edge of the rudder to make room for this, but that's not a terribly difficult modification.

Of course I haven't made the mechanical modifications for the rudder trim system either. This will be a major undertaking and entirely off the reservation as far as the plans are concern. However, I do not need to make this modification immediately; I'll probably save it for some time when I'm waiting for a future kit to ship or for more money to be made so that I can buy the next kit. Rudder trim is to be continued; for now, the rudder is "done."

29 Nov 2009

The first thing I did today was finish up a few remaining tasks on the vertical stabilizer and rudder. The vertical stabilizer just needed a couple of rivets put in. They were at the bottom of the foreward spar and I had biffed them the first time through, then really mangled the holes trying to drill them out. My solution was to get some big 3/16" AN470 rivets to fill the holes. I drilled out the new big holes with my right-angle drill kit, inserted the big fatty rivets, and drove them home with my 3x rivet gun. No problem. Aside from being huge, they look great. They're probably stronger than the original rivet, so as far as I'm concerned its an improvement. I now pronounce the vertical stabilizer complete until Section 12 (fiberglass fairings) comes along. I taped up the holes in the VS to prevent bugs from getting in, and put it out in the shed for long-term storage.

Next I put a few last touches on the rudder. First I cut a small section out of the leading edge above the upper hinge opening to make clearance for the vertical stabilizer's bonding stud.

The cut was made with a dremel cutoff wheel and was straightforward. I cleaned up the edges with a file and an edge deburring tool. As a result of the cut, the rudder's bonding stud is now directly accessible, which may aid in future inspections and maintenance, though the whole point of not having a more compact bonding attachment on the vertical stabilizer was because the rudder attachment would be harder to reach. Now they're both about the same difficulty to work with... so I'm not sure if there would be a better arrangement if the assumption was made up front that this cut would be made.

Something to think about for future builders wanting to do some bond strap work, I suppose. Regardless, I'm happy with how it turned out. The VS and rudder fit together perfectly now.

I taped up the holes in the rudder for the same reason as I had in the VS, and while doing so found three rivets at the base of the rudder spar that I had overlooked yesterday. Whoops! Not a problem, they were still fully accessible so I just squeezed them in and that was that. The rudder is now complete until Section 12 (or until I decide to make the rudder trim cuts, whichever comes first).

17 Aug 2010

Time for the first of the rudder fairings. The top rudder fairing is nice in that it requires no major modifications and won't be removable. For some reason, the fairing had a 1.25" flange on it as upposed to the 0.5" flange that the other fairing pieces had. So I had to make a big cut in this one to get it to fit in its place.

After trimming all of that off, I did a test fit only to find that the small forward flange on the fairing would run into the lead counterweight brick before the flange was fully inside the rudder skins. So I marked off another small bit to dremel off of the front flange.

With that second trim cut made, the fairing fit inside the counterweight arm of the rudder very nicely.

There were only two problem areas. First, the notch I made at the aft point for the trailing edge extrusion went too high by accident. I'll have to fill that in with microballoons or something. Also, the trailing point of the fairing falls about 1/16" short of the trailing edge of the skin. I may just file the skin corner down to be flush and call it good.

The second problem area was at the front of the counterweight arm, where I had previously bent the skins down around the lead brick. The bend has a bit of an overshoot that I hadn't previously noticed. But against the smooth line of the fairing, it's pretty obvious:

Most of that I was able to beat down with the hand seamer. The rest I'll just fill with microballoons during the blend process.

Overall, this fairing has been the best-fitting so far. The joint between the skin and fairing is really flush and smooth almost all the way around.

This fairing is complete until the filling/blending step occurrs (and that could be some time off). Next up will be the lower rudder fairing, which entails wiring up the tail light... but that's for another night.

18 Aug 2010

Started work on the bottom rudder fairing. This piece will take a fair amount of time because I'm making it removable, which isn't in the plans, and I'm adding a tail light attachment plate (from Cleaveland Tool). First up was the usual trim cuts to make everything fit. Here they are marked, with the attachment plate laying nearby:

The trailing edge notch I made with the dremel cutoff wheel like usual. The tail light hole I made by drilling successively larger holes until I had a 0.5" hole, then I went in there with a dremel sanding drum to finish it out. Next, I match-drilled the attachment plate to the aft face of the fairing:

The next bit required some creativity. AeroLEDs, the maker of the SunTail LED NAV/Strobe light that I'm using in the rudder, recently released a recommendation that the metal body of the light be grounded in addition to the black ground wire coming out of the back. Apparently this will help quell noise from the strobe light getting into the headsets and interfering with navigation equipment.

So how should I attach a ground to the tail light chassis? The attachment plate would be a good start, but it is just attached to fiberglass, so I need a bonding strap. I initially wanted to attach a small plate to the back of one of the pop rivets that holds the plate to the fairing, but there isn't enough room in there to do this. What I ended up with was milling a notch into the aft face of the plate big enough to get a ring terminal and a star washer around one of the light attach screws. Like this:

This way, when the tail light is screwed on, it presses the star washer down, causing good electrical contact between the plate, the light, and the bonding strap. The result (sans fairing) looks like this:

Next, it was time to rivet the plate to the fairing. There are six countersunk holes in the plate made for CS4-4 pop rivets, but the head of my pop riveter wouldn't fit down into the holes. So I had to fabricate a spacer. I was going to use the bushing that was previously used as a drill guard when drilling the elevator control horns, but it is steel and my bandsaw wouldn't cut it. Instead, I just lopped the ring off of a ring terminal and used the un-crimped shank.

This worked great, except that the last rivet I put in cracked the gel coat adjacent to the plate. Boo. It turns out that the fiberglass had bubbled up behind this spot so there was nothing supporting the non-structural gel coat, so it was doomed to fail. No biggy, I'll just blend over this when I blend the plate to the fairing later.

Other than the crack, I'm really happy with how the tail light install came out. It looks great test-assembled!

I went ahead and put the (provided) molex connector on the tail light wires, and wired an extra ground wire into the usually empty fifth pin. I need to get a pair of faston connectors to connect the other end of the bonding strap to the spare ground wire, then the tail light will be complete.

Continuing on with the lower rudder fairing, I match-drilled all of the holes from the rudder skin into the fairing, but rather than stopping at #30 for CS4-4 pop rivets, I am going to #27 for #6 screws. I want my lower rudder fairing to be removable so I can gain access to the electrical connectors in there. This means that I'll need nutplates behind each hole, so I used a nutplate as a template and drilled rivet holes next to each screw hole. Countersinking these was straightforward. I also went ahead and dimpled the holes in the rudder skin for #6 screw heads.

All that is left for this piece is to put nutplates on it. I'm leaving that for another day as it's time for bed.

20 Aug 2010

Got the nutplates put onto the bottom rudder fairing, rendering it complete aside from some minor blending to do around the tail light mount plate and its associated crack.

I had planned on using AN507-C632R8 stainless screws to attach the fairing to the rudder, but they are too long for the aft-most holes:

I'll probably replace these two with -6R6, or possibly just replace them all with the shorter bolts so that I have homogeniety of parts.

With the fairing done, I went ahead and finished off the tail light wiring. I spent some time on this and made it look really good. Partially because I want my electrical system to be really solid, but also because it gave me a chance to mess with my new heat gun and heat shrink label printer.

I spliced the two ground wires from the tail light into a single wire going into the rudder CPC. There shouldn't be any current off the chassis ground; it's just a shield wire, essentially. So there was no need to upsize the wire gauge. I put heat shrink over the splice, then wrapped the entire wire harness in abrasion-resistant weave, and heat shrunk the ends. The result looks like this:

Next, I knocked the pins from rudder trim out of the CPC so that I could thread them through a strain relief clamp. Both wire harnesses were put through the clamp and everything was tightened down. The result looks professional and doesn't interfere with the nearby AN507 screw.

I left enough slack between the CPC and the tail light Molex connector that I can remove the fairing without disconnecting the tail light (as seen above) or I can pull the tail light off and get to the Molex connector without taking the fairing off.

With that, the rudder is finished other than blending, trim, and paint.